Share the Love: Is Your Supplier Loyalty Putting Your Projects at Risk?

- simplybuyingltd

- 1 day ago

- 6 min read

It's Valentine's Day and we're getting a bit soppy. But before you roll your eyes, this isn't about chocolates and flowers. It's about something far more valuable to your business: supplier relationships.

Here's the thing. Most contractors treat suppliers like a dodgy Tinder date. You swipe right when you need a quote, ghost them for six months and then suddenly reappear when there's a product shortage asking for favours. Sound familiar?

Why Playing the Field Actually Makes Sense

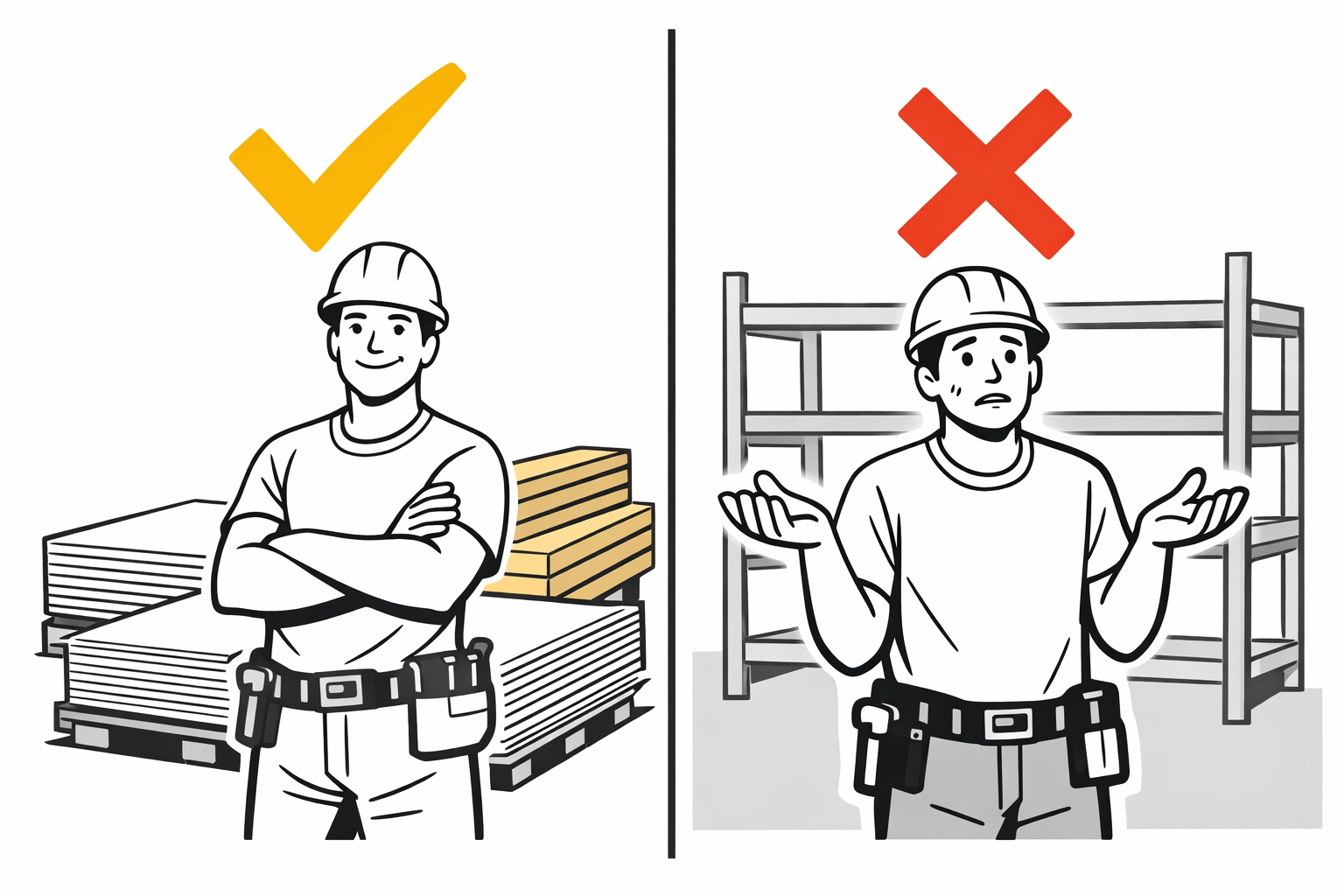

Spreading your spend across multiple suppliers isn't just nice. It's smart business. Think about it like this: when plasterboard goes on allocation or timber prices spike, who do you think gets looked after first? The contractor who's been ordering regularly for the past year or the one who only calls when they're desperate?

Suppliers have long memories. They know who values the relationship and who's just using them for a price exercise. When products get restricted and they can only supply their best customers, where do you think you'll end up on that list if you've ignored every email and never placed an order?

Regular spend builds more than just good vibes though. It builds credit limits. Every time you order, you're proving you're a reliable customer who pays their bills. That £5,000 credit limit you started with? Keep ordering consistently and watch it climb to £20,000, £50,000 or more. Stop ordering and that limit shrinks faster than your margins on a fixed price contract.

The Price Exercise Problem

We see it all the time. Contractors send quote requests to ten suppliers, take the best price and place the order with just one of them. Rinse and repeat. The other nine suppliers spend time putting together quotes and get nothing in return.

Eventually those suppliers stop responding. They know the game. They can see they're being used for price discovery while you buy elsewhere. And when you actually need them because your main supplier is out of stock, suddenly they're not so keen to help.

Our system tracks this automatically. You can see exactly how many quote requests you've sent to each supplier versus how many orders you've actually placed with them. If the ratio is way off, you know you've got a problem. More importantly, your suppliers know they've got a problem with you.

Days Since Last Order Matters More Than You Think

Here's something most contractors don't realise: suppliers close accounts due to non-trade. If you don't order for six months or a year, they assume you've gone elsewhere and shut down your account. Your credit limit disappears. Your trade pricing vanishes. All that relationship building goes in the bin.

The system tracks days since your last order with each supplier and reminds you before it becomes a problem. You might not need anything from Supplier B this month but if it's been 6 months since your last order, you'll get a nudge. Still not ordered at 12 months? Now suppliers are looking at pulling your limit. Now is the time to grab some small items or consumables just to keep the account active. It's like watering a plant. Little and often beats nothing at all.

Project Spend Split: The Reality Check

At project level you can see exactly how your spend splits across suppliers. It's eye opening. Many contractors discover they're putting 80% of their spend through one supplier and wonder why they get terrible service when things go wrong.

That supplier knows you've got nowhere else to go. They're not worried about losing your business because you've made yourself completely dependent on them. When they're out of stock, you're stuck. When their prices jump, you pay up. You've got no leverage and no backup plan.

A healthy spread looks more like 30%, 25%, 20%, 15%, 10% across five suppliers. Now you've got options. You're building relationships with multiple suppliers so when one lets you down, you've got three others ready to step in. You're not held hostage by a single supplier's stock levels or pricing decisions.

The Allocation Nightmare

Let's talk about what happens when products go on allocation. Remember the plasterboard shortage? Or when timber went through the roof? Suppliers couldn't get enough stock to satisfy demand so they had to decide who gets supplied and who gets told to wait.

That decision isn't random. It's based on your relationship and your order history. If you've been ordering regularly, paying on time and treating them like a valued partner, you're getting your plasterboard. If you've been ghosting them for months and only ring when you're desperate, you're joining a very long waiting list.

The contractors who share the love all year round get looked after when times are tough. The ones who treat suppliers like a necessary evil usually get exactly: nothing.

Building Credit Takes Time

Credit limits don't appear overnight. When you first open an account with a supplier, they're cautious. You might get £3,000 or £5,000 to start with. They don't know you yet. They don't know if you pay on time or if you're going to do a runner owing them money.

But place regular orders and pay within terms? That limit climbs steadily. After six months of solid trading you might be at £15,000. After a year, £30,000. After two years, £75,000 or more. Now you've got serious buying power across multiple suppliers.

The contractors who put all their eggs in one basket might have a £100,000 limit with their main supplier but nothing anywhere else. The contractors who share the love might have £40,000 with Supplier A, £30,000 with Supplier B, £25,000 with Supplier C and £20,000 with Suppliers D and E. That's £135,000 total credit across the network. Which position would you rather be in?

The System Shows You The Truth

You can't manage what you can't measure. The system gives you three critical views:

Quote requests versus orders placed. See which suppliers you're using for price discovery and which ones you're actually buying from. If Supplier F has received 47 quote requests but you've only placed two orders with them, they're not going to stay keen for long.

Days since last order. Get reminded before accounts go dormant. Keep every relationship ticking over with regular orders even if they're small ones. Stay on the radar so when you need them, they remember you.

Project spend split. See exactly how your spend distributes across suppliers on each project. Spot dangerous over-reliance on one supplier before it becomes a problem. Make conscious decisions about spreading the love based on real data.

This isn't about being nice. It's about being smart. Multiple strong supplier relationships give you leverage, flexibility and resilience. One strong supplier relationship gives you a single point of failure.

Making It Practical

So how do you actually share the love without making your life complicated? You don't need to split every single order across five different suppliers. That's just silly and creates unnecessary admin.

Instead, think about categories. Maybe Supplier A gets most of your timber. Supplier B handles your plasterboard and insulation. Supplier C covers fixings and consumables. Supplier D does your landscaping materials. Supplier E picks up your electrical and plumbing bits.

Each supplier gets a decent chunk of regular business in their area. You're not spreading orders so thin that nobody cares about you. You're creating meaningful relationships across different product categories. When timber prices spike, you've got leverage to negotiate because Supplier A knows you're a serious customer. When plasterboard goes on allocation, Supplier B looks after you first.

The system makes this easy because you can see your spend patterns and make deliberate choices about where orders go. You're not guessing or hoping. You're managing supplier relationships like the valuable business assets they are.

The Bottom Line

Sharing the love isn't romantic. It's practical risk management. Multiple supplier relationships mean better credit limits, better service when products go on allocation and better negotiating power on pricing. It means you're never at the mercy of one supplier's stock levels or payment terms.

The system gives you visibility over quote requests versus orders, days since last order and project spend split. Use that data to build and maintain relationships across your supplier network.

Treat your suppliers well all year and they'll look after you when things get tight. Ghost them for months then call asking for favours and you'll discover just how long waiting lists can be.

Start your 30 day free trial and see exactly how your supplier relationships measure up. Because Valentine's Day comes once a year but smart supplier management pays dividends every single day.